Our Process for Engineering R&D

The Process of PROBLEM SOLVING

We often get asked if we’ve designed such-and-so device or worked with a specific technology. We have many decades of collective R&D experience developing creative, practical solutions to complex problems, yet most of the time, the answer is ‘No’. Our engineering R&D expertise is in the process of solving challenging problems, not solving the same problem over and over. Of course, the devices we engineer may have commonalities such as injection molded parts, linear stages, optical mirrors, motors, embedded software, or printed circuit boards, but most often we’re translating concepts in a new application.

GATHERING CRITICAL FEEDBACK

We understand the concern from customers that after spending a lot of money with an engineering R&D firm, they won’t get the outcome they (or their customers) need. That’s our concern, too! So, we use an “agile” development process that provides plenty of opportunities for iteration to minimize that risk quickly and gather feedback. We’ll help you navigate the early stages when you need to validate the most important technical and commercial principles to get support from your customers, colleagues, grant committees, investors, etc.

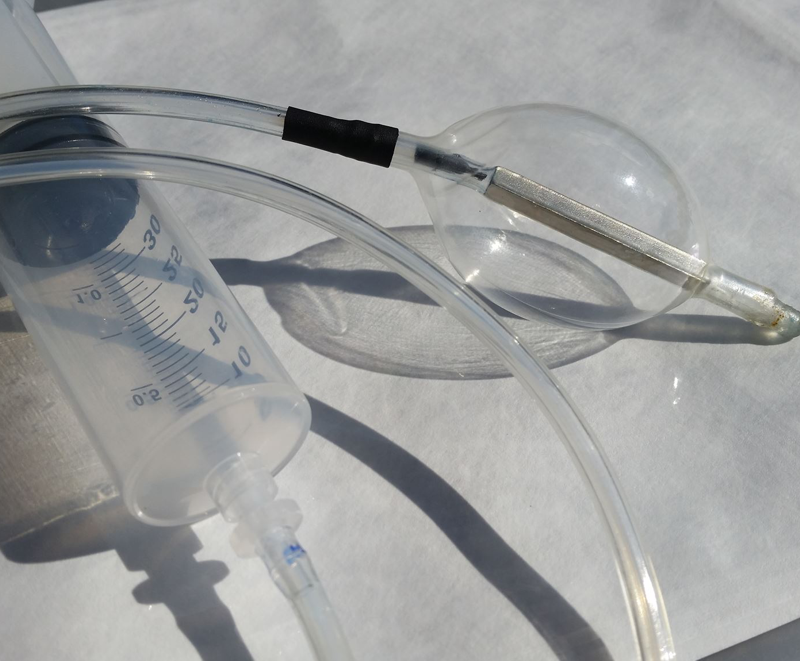

A Case Study – Functional prototypes in six weeks

Our customer was trying to non-invasively monitor Central Venous Pressure and came to us with a sensor problem. The pre-packaged sensor they were using to non-invasively characterize bloodflow was providing noisy raw data and their signals analysis algorithm couldn’t support a conclusion whether their concept worked or failed. We performed a Design Audit by quantifying the biological requirements with our customer and comparing against the sensor’s datasheet to identify performance limitations. We spent a couple of days researching alternative sensors and found an unpackaged sensor component with far better sensitivity and frequency performance. Because it was “unpackaged”, it needed additional circuitry and firmware drivers to be developed before it could start producing usable data.

Outcome of the Case Study Audit

We recommended to changing to the new sensor because of the performance gains. We provided the needed part numbers and a “blueprint” to integrate with their current data collection system. This was outside their wheelhouse, so we followed up the Audit with an additional phase of work to design and fabricate a prototype circuit board along with the firmware drivers to fully integrate it into their software so they could continue their work. Within a week of the first meeting, we’d designed a prototype PCB and sent for fabrication. Over the next five weeks, we developed the working firmware and delivered the functional prototype, including a real-time signals viewer to quickly assess sensor placement and support demonstrations. The new PCB and clean sensor data allowed them to quickly build an appropriate signals analysis algorithm, collect patient data, and prove the concept.

Wondering How to Get Your Product

Development Process Right?

OUR PROCESS

STRATEGIC DISCOVERY

Given the significant costs of bringing a product to market, it can be overwhelming (and maybe even scary) deciding which ideas are worth the investment. Root3 Labs offers what we call Strategic Discovery services to help our clients evaluate opportunities for innovation to gain confidence in their decision before we ever start engineering.

- Strategic Focus

- Need Finding

- Need Definition

- Ideation & Evaluation

EXPERIMENTAL RESEARCH

Not every project comes with a Product Specification. We’re comfortable forging ahead into unknown territory. Our proven process keeps us heading in the right direction.

- Build prototype solution concepts

- Specify a custom data collection platform

- Engineer a custom actuator

- Get everything to a remote field location

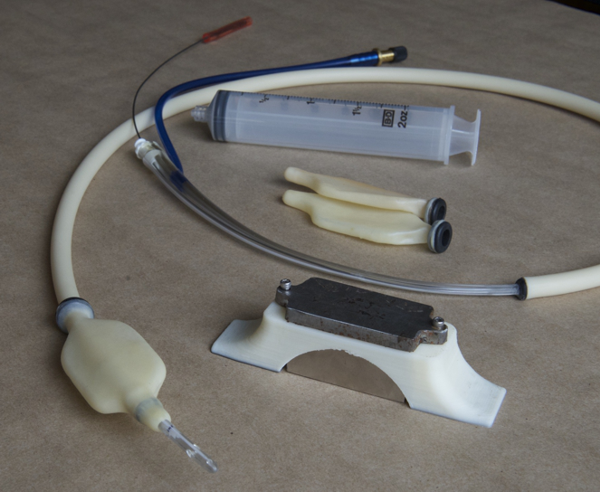

FUNCTIONAL PROTOTYPING

We’ll engineer conceptual prototypes of the riskiest aspects of the device. At this point, we’re solving the toughest challenges on the benchtop first to demonstrate the feasibility of an idea.

- Quick & dirty prototyping

- Evaluation

- Fast iteration

- Reducing risk

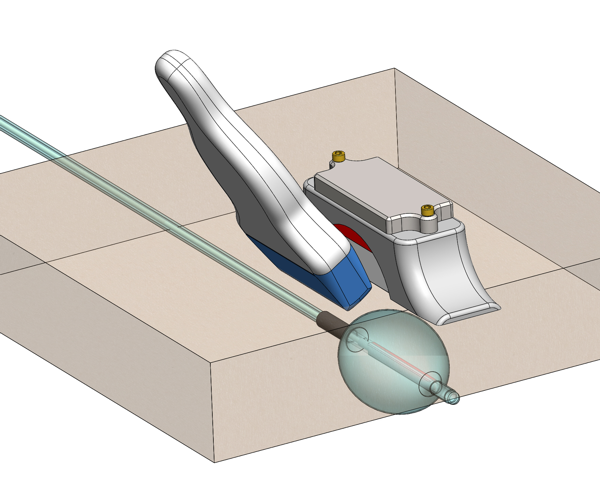

CONCEPT GENERATION

We generate concepts for the overall appearance of device as well as the functionality of some subsystems within the device. We present preliminary sketches or CAD models to the Client to convey the concepts and select a single preferred concept based on the prototype specifications.

- Review compliance standards

- System design concepts

- Appearance sketches/CAD

DETAILED ENGINEERING

For the selected concept, we engineer the detailed design & CAD modeling of the device and individual components. For this stage of development, we utilize low-volume, rapid-prototyping processes for the Alpha Prototype that may have limited functionality but offer inexpensive prototypes that are more easily and quickly developed.

- Detailed CAD modeling

- Component selection

- Prototype Fabrication

- Gather feedback

DESIGN FOR MANUFACTURING

We refine the prototype design for the desired manufacturing processes, such as stamped metal or injection molded plastic. We also support the contract manufacturer and manufacturing processes through the initial manufactured units, providing support for the applicable compliance and approval processes to ensure the quality of the product.

- Production materials

- Pre-compliance testing

- Sterility evaluation

- Manufacturing design package

PROJECT PROPOSAL

How much will it cost?

Every project is customized to meet your needs. We provide either Fixed Price or Time & Materials proposals that layout the Project Plan and define the Scope of Work. Fixed Price budgets are best-suited for projects that have well-defined deliverables and can be estimated with accuracy. Time & Materials budgets are provided for those projects with more uncertainty, technical challenges, or ambiguous deliverables. Our T&M estimates reflect our current understanding of the effort but also leave room for the flexibility to modify the Scope of Work and Deliverables throughout the project. Therefore, our T&M proposals are easily tailored to meet your goals and budget.

PROJECT STATUS REPORT

Keeping you involved and up-to-date

If you’ve ever been frustrated by not knowing how much a project is costing you or suddenly receiving a huge invoice you weren’t expecting, you’ll appreciate our weekly Project Status Reports. Throughout the project, weekly status updates keep you up-to-date on the budget, schedule, and progress. These may be emails, team conference calls, or online/in-person meetings depending on the subject matter and your preference. In addition, we have Design Reviews with your participation, complete with sketches, images, prototypes, or design documentation to review.