The Ammortal Chamber is an immersive experience that guides the user through physical, mental, and spiritual rejuvenation. It blends sound, light, vibration, an electrical field, meditation, molecular hydrogen, and breath work. The team at Ammortal had developed an initial prototype of the Chamber but had not yet achieved their vision for the fully integrated product.

As with any prototype, the first version provided some of the most critical functions but didn’t yet include the full desired feature set and user experience. Ammortal came to us with a vision for how they wanted the final product to look, but they needed a team of engineers to make that dream a reality.

Ergonomics & the User Experience

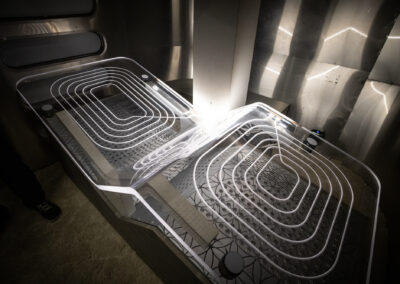

In Ammortal’s first prototype, the user laid upon a flat glass platform by sliding under a static glass enclosure above, positioning them between the Red and NIR (near-infrared) LEDs. The Ammortal team envisioned moving from the flat platform to a more ergonomic lounger profile. To achieve this, we incorporated the comfortable ergonomics of the Neutral Body Position that’s been studied and validated by NASA into the platform design.

The initial prototype included a LightDeck positioned above the user, but there were concerns about how to move the LightDeck out of the way for the ease of entering and exiting the unit. The single support would provide an open design, to eliminate the feeling of a tight space as much as possible while maximizing the therapeutic effects of the LEDs. This desired design was no small feat due to the weight and size of the LightDeck. We achieved this sleek vision by leveraging finite element analysis (FEA), strategic weight distribution, and prototyping.

System Integration & Controls

The Chamber integrates a variety of therapies. However, to create a unified experience, we wanted to create a simplified interface and robust control system. Since each component had its own internal control mechanism, we developed a custom PLC system (programmable logic control) capable of being configured appropriately. Since PLCs are not used in your typical Audio/Visual system, we had to develop electronics and embedded firmware to decode the multi-channel, digital audio files, translate them to analog signals, and amplify them before sending to the various speakers, subwoofer, and vibration transducers. For the user, we added a remote tablet for wireless control of the user preferences and settings which required developing a custom GUI (Graphical User Interface) and communication with the Chamber controller via Bluetooth Low Energy (BLE). Similar to other IoT (Internet of Things) devices in your home, both the Chamber controller and the tablet software can be automatically deployed and upgraded over the internet for future feature implementation.

Design for Delivery

One unique aspect of the Design for Manufacturing considerations was the requirement to install the device in medical spas and homes around the world. We had to think through packaging the 800lb (360kg) Chamber for freight transport as well as how it could be brought up stairs and fit through doorways. The system was designed to fit through the typical interior door and includes installable casters. If the Chamber needs to be installed upstairs, it breaks down on-site into light-weight components that two people can reasonably carry and all the electrical connections are accessible and unique to ensure they’re reassembled properly.

In the meantime, our customer is bringing the Chamber to customers and conferences and unloading it from a van time after time just didn’t make sense. We helped them install the Chamber in an Airstream trailer to create a mobile experience without the setup. Connect with Ammortal to find out how to Experience the Chamber for yourself.

“The team at Root3 found the answers to the many difficult engineering demands we placed on them, enabling us to realize our dream design. We are forever thankful.”

-Brian Le Gette, CEO at Ammortal Inc.

Highlights

DESIGN FOCUS

- User Experience

- Aesthetics, Ergonomics

- System integration of multiple technologies

- Electrical Safety

- Embedded Software Development, Mobile Application, Firmware

- Design for Manufacturing, Assembly, & Delivery

FABRICATION

- Sheet metal

- Thermoformed Plastics

- Embedded electrical coils

- Custom electronics and control system

- CNC machining

- Material selection