Bioprocess Automation: Transforming 24/7 Manual Monitoring into Autonomous Control

Our client came to us with a novel pharmaceutical bioprocessing platform and a significant challenge: their purification process required 24/7 human monitoring for up to 14 days at a time. Imagine having to watch a slow moving chemical reaction for 336 hours without a break! That’s an expensive snooze-fest!

This seemed like the perfect job for a computer, and a waste of time and money for the brilliant scientists stuck watching.

We jumped in to help this client add sensors and a user interface for real-time data monitoring, data logging, automated system control, and optional manual system control. This effort transformed this expensive, manpower intensive process into a streamlined, automatically controlled system.

The Problem: Round-the-Clock Bioprocess Monitoring

When the client first came to us, they had a benchtop setup and a vision of the sensors they wanted to use for automation. The end goal:

An automated system that could monitor, control, and collect data on this purification process for two week stretches, while still allowing for manual user monitoring and control when needed.

The complexity of the system was substantial – we needed to control 5 pump channels and monitor 28 sensors measuring pH, conductivity, flow rate, pressure, pump status, and mass.

However, we needed to do more than just replace human eyes with sensors. The system also needed to be intelligent enough to make real-time decisions to keep the process running smoothly for two weeks at a time.

By the Numbers:

- 14 Days of 24/7 Monitoring

- 28 Sensors

- 5 Pumps

Our Approach to Bioprocess Automation

We broke this bioprocess automation effort into three distinct phases of work:

1. The Basics: Get the sensors integrated and collecting data

2. Adding a User Interface: Develop a user interface to display the data, log the data, and offer manual control of the system

3. Adding Closed-Loop Control: Add closed-loop feedback based on user-defined system parameters to complete automation

Project Milestones!

Defining these intermediate milestones are critical to our development process. Each stepping stone builds on the last, allowing us to establish a strong foundation before diving into the layers of complexity. This phased approach also gave us the opportunity to gather early user feedback to refine the design and maintain alignment on the vision throughout the project.

Phase 1: Sensor Integration and Control System Architecture

Step One: Integrating 28 sensors into the system design, both mechanically and electrically. These sensors would become the “eyes and ears” of our bio-process automation system, monitoring everything from pH levels to flow rates across all 5 pump channels.

Once all the hardware was integrated, we started developing base software to interface with the sensors, log data, and control the pumps. This work can be tedious, but it was essential since these components would provide the building blocks for everything that followed.

By the end of Phase 1, we had a system that could collect data and respond to basic commands, setting the stage for even more sophisticated control.

Phase 2: User Interface Development for Real-Time Process Monitoring

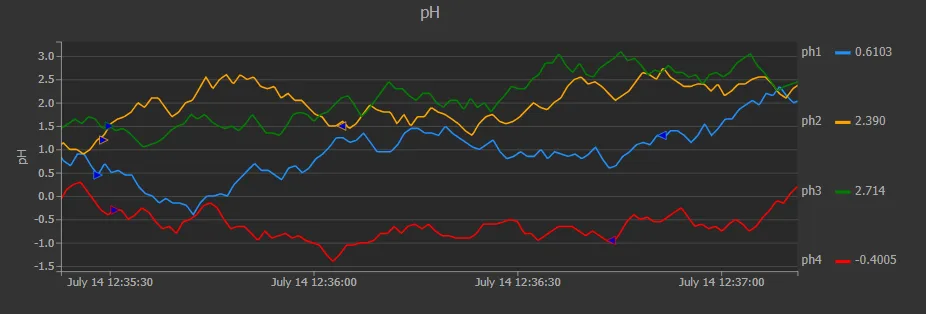

With the sensors now talking to the software, we turned our attention to the human side of the equation. Phase 2 focused on building a user interface that could display data in real-time (both numerically and graphically) while logging everything for post-processing and analysis.

This phase was highly iterative. We began with a concept, filled in the details, and then added features as they became relevant to the workflow. The client used early versions of the interface and provided feedback based on their actual testing needs. This early end-user input proved critical to the development process.

As the client stress-tested the software, we gained two valuable outcomes: real end-user feedback on the interface (ease of use, features, bugs) and crucial data defining the normal operating ranges for each sensor. This data would go on to become the guardrails for our automated control system in the next phase.

Phase 3: Implementing Closed-Loop PID Control

This phase was where all of our work so far came together to make magic: transforming the system from fully monitored to autonomous. With initial testing complete, we had a clear picture of how to optimize the software for user experience and the system behavior patterns needed to implement automation.

We created a framework for PID control based on the data collected during Phase 2. Since the actual purification process takes 14 days to complete, we developed an innovative testing approach using a secondary pump and control software to simulate accelerated failures. This allowed our team to validate base functionality and fail-safes without waiting two weeks for each test cycle.

Once the framework was solid, we moved on-site for initial PID tuning with the actual system. The system ran through abbreviated tests as we dialed in the parameters – a time-intensive and iterative process that required both patience and precision. After several iterations, we helped the client achieve their goal: successful 14-day runs that concluded with zero human intervention.

Engineering Solutions for Pharmaceutical Process Validation

Remote Testing and Simulation Strategies

Limited access to the full system forced us to innovate our testing approach. In an idea world, we would have had a duplicate setup in our facility for iterative testing. Since that wasn’t possible, we developed a three-pronged strategy:

- Simulated Testing

- Remote Client Testing and

- Strategic In-Person Testing

Simulations became our secret weapon for rapid validation with minimal resources. From day one, we had the software generating dummy data to evaluate data flow and user interface functionality. This approach continued throughout development, allowing us to test new features without risking the actual bio-process.

We also set up a secondary pump to simulate expected system failures. For example, we could choke fluid flow to trigger alarms and test emergency stops. To the sensors, the data looked identical to a real failure, but we saved 14 days and valuable resources with each simulated test.

As features matured, we released stable versions for the client to trial remotely, maintaining continuous communication that helped guide user experience improvements and catch bugs early. At major milestones, we conducted strategic in-person testing to handle hardware setup, PID tuning, and final validation.

Managing Automation Requirements in Bioprocessing

Creating something truly novel means navigating unknowns. We were automating a process that wasn’t fully understood – even by the client. While automation would enable 14-day runs, the client could only loosely define the process parameters and required user interactions at the project’s start.

This uncertainty demanded flexibility in our feature development, which naturally invited scope creep. We began with a wish list of desired features that would need to be defined as the system was tested. New features? Inevitable. Changes? Guaranteed.

The key was maintaining focus on the end goal: an automated system capable of 14-day operation. We distinguished between essential features (like time-stamped error logging for data post-processing) and nice-to-haves (like user-manipulable process diagrams) that could wait until after we had a stable, validated solution.

Bioprocess Control Systems

Our bioprocess automation solution delivered several key technical capabilities that transformed the client’s manual process into an autonomous system:

Full Hardware Integration

- Integrated 28 sensors across 5 pump channels

- Successfully monitoring pH, conductivity, flow rate, pressure, pump status, and mass

- Real time data acquisition

Custom Control Software

- Developed proprietary software featuring:

- Automated closed-loop control algorithms

- Complete data logging and analysis capabilities

- Intuitive user interface for monitoring and manual override

PID Control Implementation

- Engineered and tuned PID controllers to maintain the process within defined parameters

- Pump speeds and flow rates automatically adjusted based on sensor feedback

Robust Testing Framework

- Created simulation and testing protocols that validated the system without needed 14-day long runs

- Significantly accelerated development cycle

Results: From Concept to Continuous Operation

The result? The client successfully ran 14-day trials with automated monitoring and data-logging. The user interface allowed the client to check in on the process status remotely without babysitting it 24/7. The comprehensive data and error logging enabled thorough post-processing, ultimately helping them validate their novel bioprocessing platform.

This bioprocess automation project transformed an unsustainable manual process into a sophisticated, autonomous system. By combining electrical engineering expertise, custom software development, and innovative testing strategies, we gave our client their time back while advancing their pharmaceutical innovation. The system now runs continuously, collecting the critical validation data needed to move their platform from concept to commercialization.

This was just one of many steps along the road from novel idea to manufactured product, but it was a crucial one – proving that their bioprocessing platform could operate reliably at scale, without constant human intervention.

Developing a Novel System or Device?

Contact Root3 Labs for mechanical prosthetic development, medical device prototyping, and engineering services that put users first.