Disinfecting Dialysis Tubing with Relavo's PeritoneX™

Relavo is a medical device company led by a female-founded team of biomedical engineers from Johns Hopkins University. They are working to minimize the risk of infection with at-home dialysis systems.

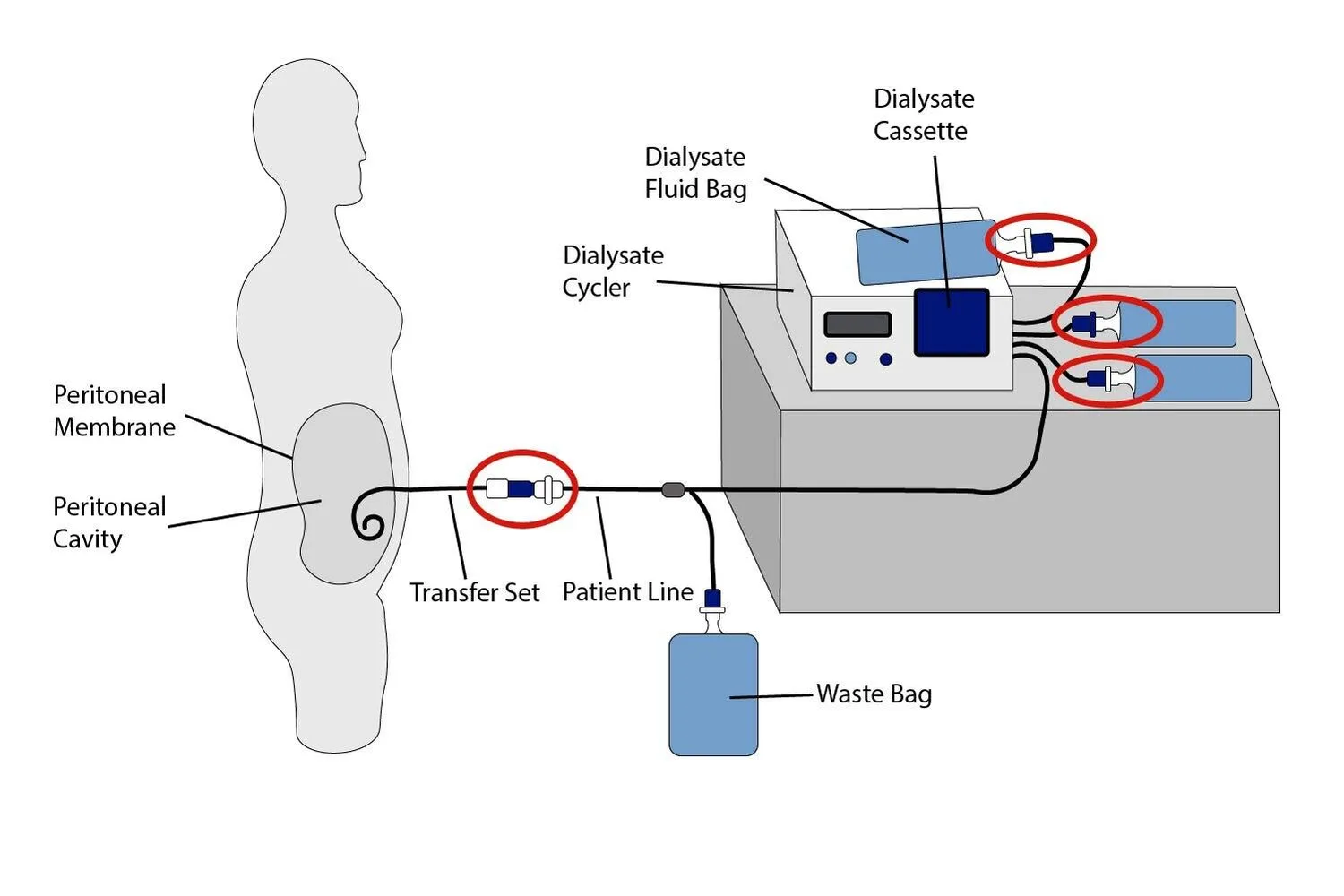

Their device, the PeritoneX™, makes it possible for more patients to receive kidney treatment from the comfort of their own home, rather than spending 15-20 hours per week in a dialysis clinic. Peritoneal dialysis (PD) is a type of kidney treatment that would allow for in-home dialysis treatments. Currently, only 10% of patients in the US with kidney failure utilize it due to the risk of infection.

Relavo’s device, the PeritoneX™, helps mitigate this problem. The device functions by disinfecting dialysis tubing within the PD system. It works by injecting a disinfectant solution into the PD line and connectors, and then extracts the solution after a short dwell time. In testing, this resulted in greater than a 4-log reduction in bacterial growth.

Peritoneal Dialysis diagram from relavomedical.com

Developing a Disinfectant Device

Initial proof-of-concept prototype

Root3 Labs supported the development of the PeritoneX™ through several design phases. Our initial proof-of-concept prototype consisted of a timing and locking mechanism which injected disinfectant and extracted the fluid after a set dwell time.

At this stage of design, we’re only concerned with proving that our design idea is feasible. This early prototyping phase is crucial to the development process. It allows us to focus purely on the technical aspects of our initial concepts and answer the first crucial question: “Will this work?”

Later, we’ll look at more pieces of the overall design puzzle which will help inform our decisions as we move through several rounds of iteration on the design. Don’t fall into the pitfall of trying to address every single design consideration all at once; think about your MVP (Minimum Viable Product) at each phase of design and focus on only those aspects of your design.

Learn more about Functional Prototyping, why we love it, and why it’s critical for successful product development.

In the next phase, we developed a benchtop prototype which integrated electrical components and controls to create a simplified reusable unit. We evaluated linear actuation methods to compare cost and simplicity, refined electronic controls using an Arduino platform, designed a basic enclosure to house the components and developed a mounting mechanism for off-the-shelf syringes.

In a third phase of development, we began to refine the design towards a manufacturable product. We selected an off-the-shelf linear actuator to replace the 3D printed lead screw, added a battery pack, and updated the electronic controls and firmware. Compare the videos of the Phase Two and Phase Three devices below!

As the device development progresses, Relavo continues to have success in gathering funding. The company has been granted countless awards and investor support since its inception. That includes receiving NSF SBIR awards, being awarded second place in the San Diego Angel Conference, and ranking as the top 20 most promising Baltimore tech company start-ups in the region.

This female-founded company deserves a huge shout out! We can’t wait to see what’s coming next from them.

Highlights

DESIGN FOCUS

- Proof of Concept Prototyping

- Design for Manufacturing

- Ease of Use

FABRICATION

- Low-Cost Prototyping

- 3D-Printing

- Electronics

- Programming