Trays for 8mm and 16mm manual film development

Our client has a business developing Super 8mm and 16mm film for a variety of customers including hobbyists, artists, and major brands who want to use this medium to capture and create moving images with a unique aesthetic. Given the dominance of digital for producing modern video, traditional film development is a fairly small market, which brings unique challenges to the business. Our client has been using film development spirals originally produced in the USSR (as evidenced by the Cyrillic characters molded into them) and acquired second-hand. The supply and quality of these tools has been dwindling in recent years, however, and our client asked us to produce a similar kit with some extra features to enhance their functionality in the client’s processing lab.

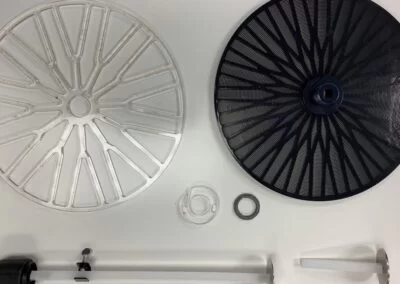

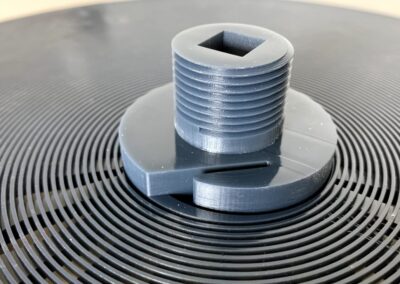

Something that seems simple enough was complicated by several factors, all inter-related. First, the spirals rely on small geometry and tight tolerances so the film can smoothly be pulled into the assembly, with the operator relying on feel while working in darkness. Second, the film development chemicals significantly limited the materials which could be used. Lastly, the quantity to be produced meant they couldn’t be cost-effectively made exclusively with the processes used for prototypes or one-offs, but wasn’t enough to justify high-volume methods like injection molding. Root3 went through several design iterations balancing all of these factors. In the end, we produced custom components using a combination of lightly-modified off-the-shelf parts, laser-cut and machined acrylic, and urethane casting. The result is a design that meets the client’s current needs and budget and offers flexibility to produce more small batches as needed in the future.

Highlights

DESIGN FOCUS

- Tight tolerances

- Chemical compatibility

- Ease of use

- Manufacturability

FABRICATION

- Light machining

- Laser cutting

- Urethane casting

CUSTOMER

- Negativeland, LLC