Eat with dignity.

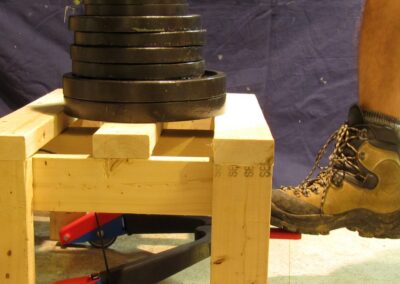

We designed an assembly of injection molded parts that allow the flexibility to suit a wide variety of chair dimensions and meet the Customer’s product specifications. To meet the desired maximum load capacity, we performed numerous calculations on all of the components to ensure the maximum stress was far below the ratings of the selected materials. 3D-printed prototypes were fabricated to evaluate the look, feel, and functionality of the device. The design was refined, and multiple sets of CNC machined prototypes were fabricated for full-strength testing before initiating the tooling expense for injection molding.

This product was recently showcased in the 2013 “Best of NeoCon” Entry Level 1 category and will be available from ComforTek Seating.

Highlights

DESIGN FOCUS

- Cost reduction

- Appearance

- Ease of Installation

- Ease of Use

- Strength of Materials

FABRICATION

- 3D Printed ABS

- CNC Machined ABS

- Injection Molding

CUSTOMER

- Jenry LTD

- Millie Mova

- ComforTek Seating