StetPulse is a prototype UV-C sterilization system to be used in hospitals/clinical settings for stethoscopes. The original prototype was designed and built by a team of undergraduates at Johns Hopkins.

Doctors and other medical professionals use their stethoscopes to listen to the lungs and heart of patients. In hospitals, stethoscopes may become a vector for viral or bacterial transmission between patients if not sanitized between each use. To mitigate this risk, StetPulse’s prototype leverages ultraviolet (UV) light to sterilize up to two stethoscopes at a time.

Iterative Prototyping

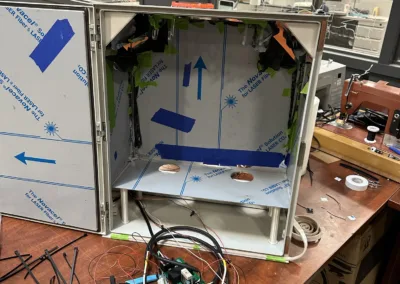

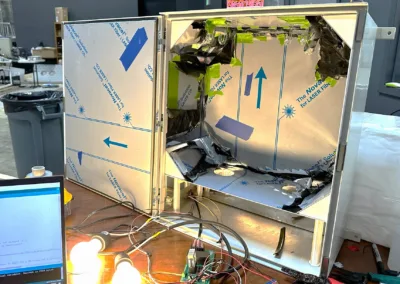

Because the StetPulse team already had their own design and prototype, our team at Root3 Labs was able to jump right into iterative prototyping for our first phase of work. We started with the StetPulse’s original prototype, and worked together with their team to improve the overall design.

First, we needed to perform quantitative testing to determine the device’s sterilization effectiveness. We used photochromatic UV dosimeter cards to collect that data. Then, using that data, we were able to determine that we needed to change the UV wavelength to eliminate the production of ozone and improve overall sterilization.

There were several elements we aimed to improve upon. The enclosure itself needed adjustments to ensure homogenous UV exposure, as well as to properly compartmentalize the electronics. There also needed to be considerations for the electronics themselves. They needed to be redesigned for reliability and safety, while still maintaining existing user safeguards. To improve the user experience, we had to look at the UI features of the StetPulse, as well. It needed to reliably and aesthetically display countdown timing to the user.

Design for Manufacture

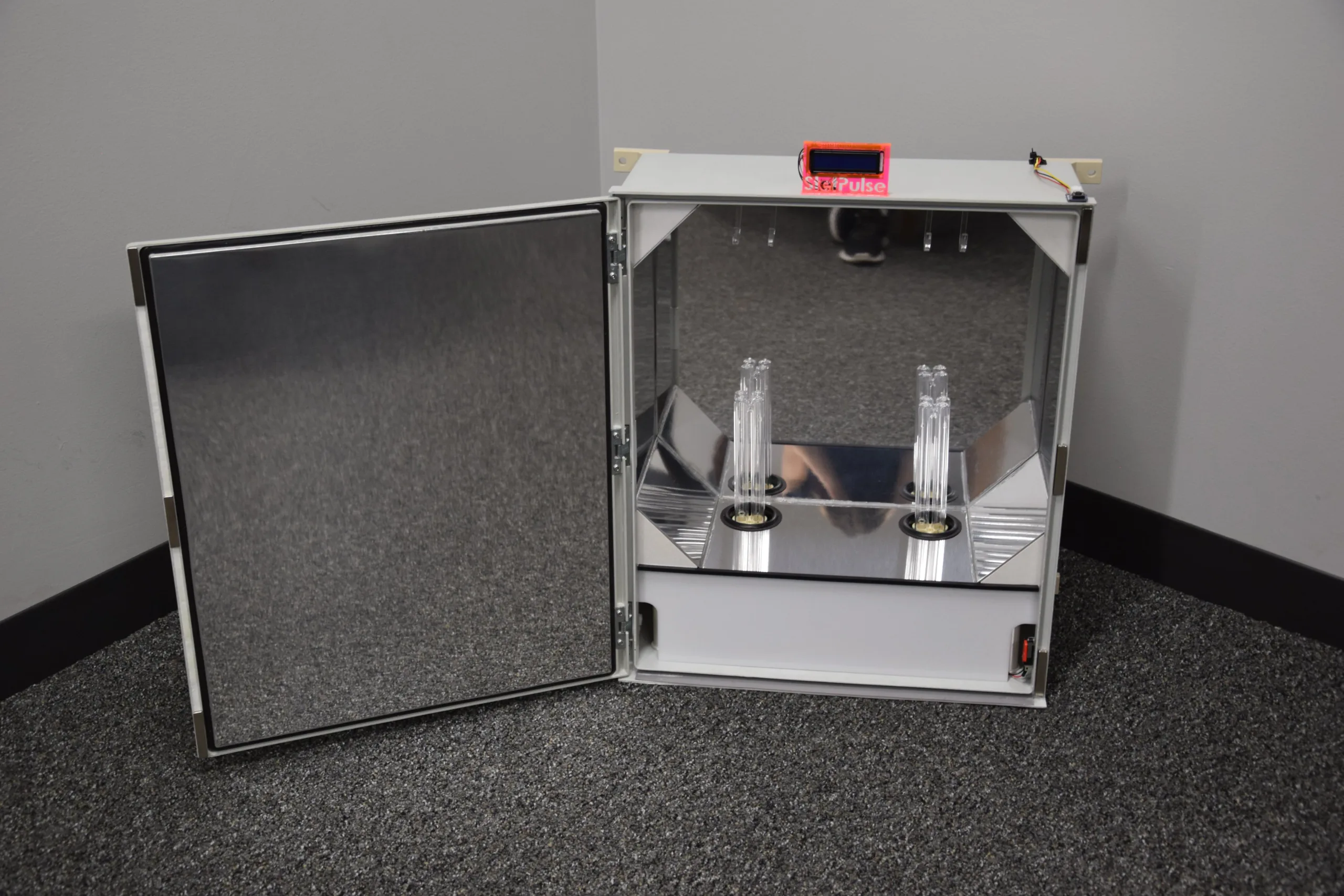

The next phase consisted of implementing, testing, and then iterating on our desired changes until we reached the final design. We changed the enclosure to a highly reflective mirror walled box. The mirrored interior was an aesthetic upgrade that also maximized UV exposure to all surfaces of two stethoscopes simultaneously. It provides sterilizing levels of ultraviolet light in one minute. We redesigned the electronics, packaging them to fit neatly and unseen within the new enclosure. The redesign also kept in place necessary safeguards, like having the UV bulbs immediately shut off if the enclosure is opened early.

Using our unique design process, we were successfully able to iterate on StetPulse’s design and help take them from prototype to product.

Highlights

DESIGN FOCUS

- UV-C Sterilization Coverage

- Material Reflectivity

- Prototype Safety

- Electronics Reliability

FABRICATION

- Sheet Metal

- Electronics Prototyping

- Foam

- 3D Printing