Moving from prototype to production requires more than just proving your concept works. You need to prove you can deliver that concept reliably, at scale, and at the right cost. Here’s what changes from the lab to the production line, and how to plan for it from Day One.

Chad has spent over 15 years leading complex engineering projects in medical device development and defense systems. He’s been hands-on from early-stage prototyping to full-scale manufacturing, giving him unique insights into the challenges of bringing devices to market. Chad is always thinking about how to improve the development process, so we convinced him to share some of those musings with you!

How Engineering Requirements Change from Prototype to Production

Performance is Just the Starting Point

In the early stages of R&D, your main question is simple: does it work? You’re testing in controlled lab conditions, focusing on proving that your concept can deliver the performance you need. That’s important, but it’s not enough.

When you move from prototype to production, the questions get harder. Will it work reliably? Can it handle real-world conditions? How will it scale?

Production demands durability and reliability. Your device needs to perform not just once in ideal conditions, but consistently across thousands of units in unpredictable environments.

Planning for Things to Go Wrong

The workshop is a controlled space. Production is not.

In the real world, you’ll encounter error conditions and edge cases that never showed up during prototyping. For electronics, that might mean adding fuses to handle power surges, or battery monitoring circuits to prevent over-discharge. For mechanical systems, it means accounting for tolerance stack-up – making sure parts fit together properly even when every component is at the extreme end of its manufacturing spec.

If your prototype works perfectly in the lab but hasn’t been designed with these scenarios in mind, you’re going to run into problems when you scale.

Component Selection for Product Development

Avoiding Obsolescence Before Scaling to Production

One of the easiest ways to derail your production timeline is to build your prototype around components that won’t be available when you’re ready to manufacture.

If you’re shopping on SparkFun or Amazon, you probably don’t have visibility into how long those parts will be supported. That’s fine for earliest prototyping, but it’s a risk when you’re planning to build hundreds or thousands of units.

Enterprise-grade components come with dates of obsolescence and support timelines – typically 5 to 15 years. For example, Raspberry Pi compute modules list their support end dates right in the specs. That kind of information lets you plan ahead instead of scrambling to redesign around a discontinued part.

Vetting Suppliers for Long-Term Reliability

Where you source components matters!

Distributors like DigiKey and Newark offer counterfeit protection and part traceability. When you order a specific part number, you’re getting that exact component from that exact manufacturer. That consistency is important when you’re scaling up.

Some distributors use their own part numbers and don’t always trace back to the original manufacturer. That’s usually fine for things like screws – they’re substituting based on material and thread specs – but for electronics or critical mechanical components, you want to know exactly what you’re getting.

How We Prevent Common Prototype to Production Failures

At Root3, we follow a progression based in Engineering Principles: 3D printable first, then machinable, then injection moldable.

Each manufacturing process has different capabilities and constraints. 3D printing is great for early prototypes because it’s fast and flexible. Machining offers tighter tolerances and works with a wider range of materials. Injection molding is ideal for high-volume production but requires more upfront tooling investment.

The key is to design for the shop before you design for the factory. Early on, you can combine functionality into a single 3D-printed part to test your concept quickly. But you need a vision for how that part will eventually split into multiple injection-molded or machined components when you scale up.

1. Designing with Production in Mind

You don’t need draft angles, uniform wall thickness, or every production feature in your first prototype. Over-engineering too early just slows you down.

But you do need to think about how your design will transition to its final manufacturing process. If you’re 3D printing a complex part now, can you see a path to breaking it into simpler components later? Are you designing with tolerances that will work when parts are injection molded?

Having that vision lets you move fast in R&D without painting yourself into a corner.

2. Design for Assembly, Repair, and Service

Production isn’t just about making parts – it’s about putting them together, and eventually taking them apart.

Design for Assembly means thinking about how quickly and reliably your product can be assembled on a production line. Can you reduce part count without losing functionality? Are fasteners accessible? Do components align easily?

Design for Repair and Service means thinking about how your product will be maintained over its lifetime. If a component fails, can it be replaced without disassembling the entire device? That kind of serviceability builds trust with customers and reduces long-term costs.

And don’t forget about value engineering! You want to make sure you’re optimizing for cost, weight, and durability. There are smart tradeoffs to be made at this early stage to improve manufacturability without compromising performance.

Design for Manufacturing in the Real World

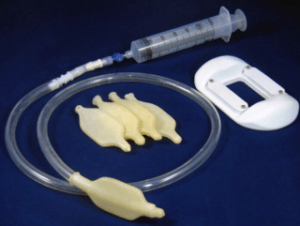

When a client came to us with their medication flavoring system, we helped them optimize their design for high-volume manufacturing. By refining their assembly process and material selection early, we reduced production costs while maintaining the reliability their pharmacy customers depend on.

When Should You Start Considering Design for Manufacturing?

The best time to catch manufacturing problems is before you finalize your design.

A design with fancy bells and whistles that can’t be manufactured is just an expensive prototype.

The balance is this: stay flexible in early R&D, but keep a clear path to manufacturing in mind. You can refine tolerances, add draft angles, and optimize for assembly later – as long as you’re not designing something that fundamentally can’t scale.

Think of it as designing with one eye on today and one eye on tomorrow. That approach lets you move quickly without creating expensive problems down the road.

Need Help Bridging Your Prototype to Production?

Talk with one of our engineers today. We’ll answer any questions about how we can help you solve your technical challenges.

This is a no-obligation introductory call, not a hard-sell. If we’re not the best engineering partner to help right now, we’ll let you know.