Our Services

Prototype Fabrication

Quickly build & improve prototypes in our Workshop

Embedded Systems

Electrical engineering and design.

Military & Defense

Early-stage concepts to field-tested prototypes

Medical Device Design

From design to documentation and beyond.

The Root3 Labs Difference

Here at Root3 Labs, we follow a First Principles process of breaking down obstacles into their most fundamental pieces. Then we get to work with the next step: Designing, Prototyping, & Testing solutions iteratively before putting it all back together.

We look at design details thoughtfully from different perspectives, like how they integrate with other aspects of the product. We look at the material selection, manufacturing cost, assembly, user experience, and beyond – which ultimately leads to a quality product.

Wondering how to get your Product Development Process right?

Our extensive on-site workshop allows our engineers to fabricate many of our prototypes in-house, then quickly iterate & refine them rather than wait more for changes to be made by outside vendors.

Every project is customized to meet your needs. We provide either Fixed Price or Time & Materials proposals that layout the Project Plan and define the Scope of Work.

Solving Hard problems

For Visionary Customers

Solving Hard problems

For Visionary Customers

OUR project PORTFOLIO

Gallery

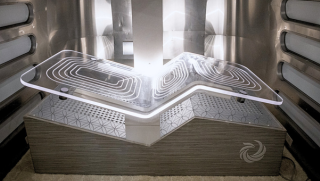

Wellness Product Engineering

The Ammortal Chamber is an immersive experience that guides the user through physical, mental, and spiritual rejuvenation. It blends sound, light, vibration, an electrical field, meditation, molecular hydrogen, and breath work.

CPAP Cannula for Infants

Premature babies need specialized care, but traditional CPAP cannulas can be uncomfortable and inefficient. We worked with Dr. Mohamad to develop his solution: a single-piece, comfortable, and effective cannula designed specifically for premature babies.

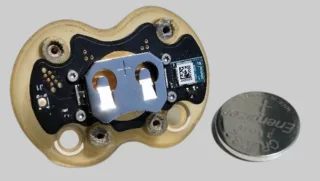

Smart Pacifier

We worked with Brainchild Technologies, LLC, to develop a smart pacifier that uses embedded sensors to monitor the suckling behavior of newborn babies. The pacifier communicates intensity and frequency data to a fellow Bluetooth enabled device in real-time.

Our Prototyping Workshop

Contact Us!

11408 Cronridge Dr Ste C

Owings Mills, MD 21117 USA

39°26’10″N 76°46’34″W

Subscribe

Get an inside look at our process for exclusive insights you can’t find anywhere else, delivered right to your inbox.

Don’t worry, we won’t sell your contact information or flood you with spam. Plus, you can unsubscribe at any time.